- Total capacity of 28 KW.

- Largest 12 KW.

- Table size 3000 * 1500

- Pallet system up to 30 magazines.

- Up to 50mm in thickness.

- Table size 10000 * 2000.

- Cutting of aluminum, black and stainless steel

- Up to 300mm in thickness.

- Table size 13000 * 3000.

- 6 burners

- Fast process time

- Multiple processors are integrated into one process

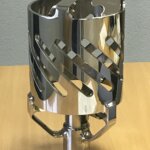

- A wide selection of saws, and thus quick conversion.

- Fully automatic sawing and drilling.

- Low cost with low staffing

- Edge press up to 225 tons and 4250mm rail

- 7 bending machines

- 2 robot-operated bending machines

- There are big savings on robotic welding, as the robots usually are 3-5 times faster than manual welding.

- Opportunity in collaboration with our customers to offer items from prototype to serial production.

- Uniform and controlled welding processes.

- There is a big saving on robotic welding, as the robots are usually 3-5 times faster than manual welding.

- Opportunity in collaboration with our customers to offer items from prototype to serial production.

- Uniform and controlled welding processes.

- Section 7 lathes, 3 of which are with robot.

- 8 machining centers, 3 vertical and 5 horizontal.

- 2 centers with pallet system (10 pcs)

- Max. size 1300 * 1300 * 1300mm

- Paint

- Electroplating

- Polishing

- OEM supplies Siemens / Phillips

- Great knowledge of different standards

- Test and control at all levels

- Direct deliveries to the whole world

- Security of supply

- High quality

- Product Optimization

- Logistics

- Customer stores in house.

- A proven supply chain.

- Stock management system and barcodes on all items.

- Full traceability of productions.

- Internal lifting capacity of 16 tons.